Easy-Laser XT660 – Dual Dot Laser

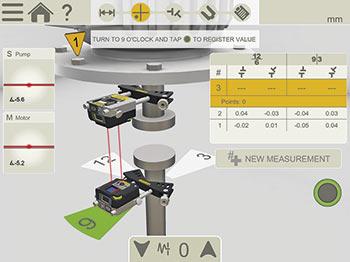

The XT660 measuring units utilize dot laser technology. This makes it possible to measure larger machines and longer spans than line laser systems. It also provides higher accuracy when backlash in the coupling is present. In addition, dot laser allows you to check more things when installing a machine, e.g. twist of foundation and bearing clearance.

With the XT660 you have a choice of several different measurement methods, e.g. continuous sweep and multipoint. This gives you the flexibility you need to achieve the perfect measurement result.

The XT products are rugged, rated both IP66 and IP67 water and dust proof. Along with long operating times, this guarantees you will be able to take on and finish even the tougher jobs.

User-friendly

Use the rugged Easy-Laser XT12 display unit, or install the free XT Alignment app on your iOS or Android device. The intuitive user interface guides you through the measurement process.

Unique documentation possibilities

The XT11 display unit has a 13MP camera. You can also get the XT12 display unit with a built-in IR camera. This means you can add a thermal image of the machine before and after alignment. You can easily create and share a PDF report containing all measurement data and images.

Measurement Programs

The featured programs below are the most commonly used with this system.

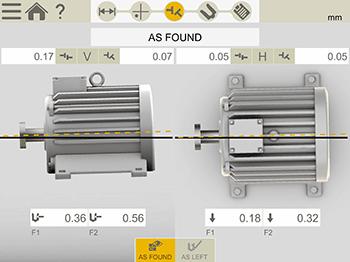

Horizontal machines

The user interface is intuitive and guide you through the measurement process. It is animated and zooms into the most important things for each step. You can save the measurements of a machine for as found and as left in the same file.

Vertical/flange mounted machines

For measurement and alignment of vertically and flange mounted machines.

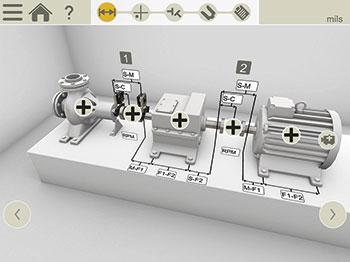

Machine train (3 machines)

For alignment of machine trains with three machines. You can pick the reference machine manually or let the program choose one that will minimize the need for adjustments.